Apollo Foam provides innovative, custom engineered polyethylene foam solutions globally

Apollo Foam provides innovative, custom engineered polyethylene foam solutions globally

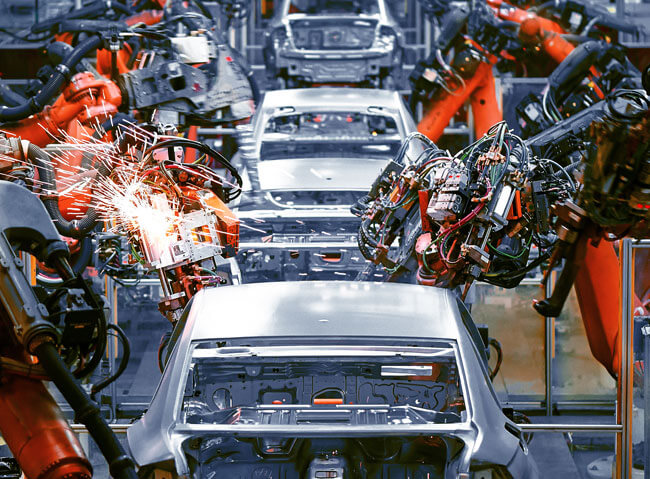

Apollo Foam provides cost-effective polyethylene foam materials to meet the demand for lightweight, robust and technically demanding sealing technology within the automotive industry.

Our range of polyethylene foams offer lightweight technology coupled with flame retardant additives giving excellent resistance to high temperature.

Polyethylene foams also offer low water permeability and have excellent thermal insulation depending upon the automotive application. Polyethylene foam can also have a pressure sensitive adhesive applied to give an extra dimension and opens up other areas of applications in the automotive industry.

Polyethylene foam can be converted into plain or self adhesive gaskets, seals, strips and washers, here are some of the benefits

Polyethylene foam comes in a range of densities from the very soft 15kg per m3 up to 100kg m3. If the lowest density Polyethylene foam is still too firm, we can then look at our range of open cell polyurethane foams for the application.

Supplying automotive manufacturers in the UK and Europe, we machine lineside foam tray and tote stillage inserts to optimise both productivity and stock control. These can be manufactured to your bespoke design for your application.

The Polyethylene foam can be dual coloured for the ease of identification – either for missing tools or components.

The dual-colours can also be custom made to your branding, offering corporate colours throughout the foam, offering a fully customised design that is heat sealed to ensure there is no foreign object damage.

Once produced, the foam routings can be individually identified by laser engraving your part number onto foam, this has no detrimental effect on the integrity of the foam and gives a professional touch to packaging and storage.

We also offer a range of mechanics mats and kneelers which can be manufactured to your requirements in dual colour and finished with your company logo, website, or telephone number.

Our polyethylene foams are converted to our customers’ individual requirements from split sheets, pressed foam fitments, waterjet and routed polyethylene foam components for all market sectors.